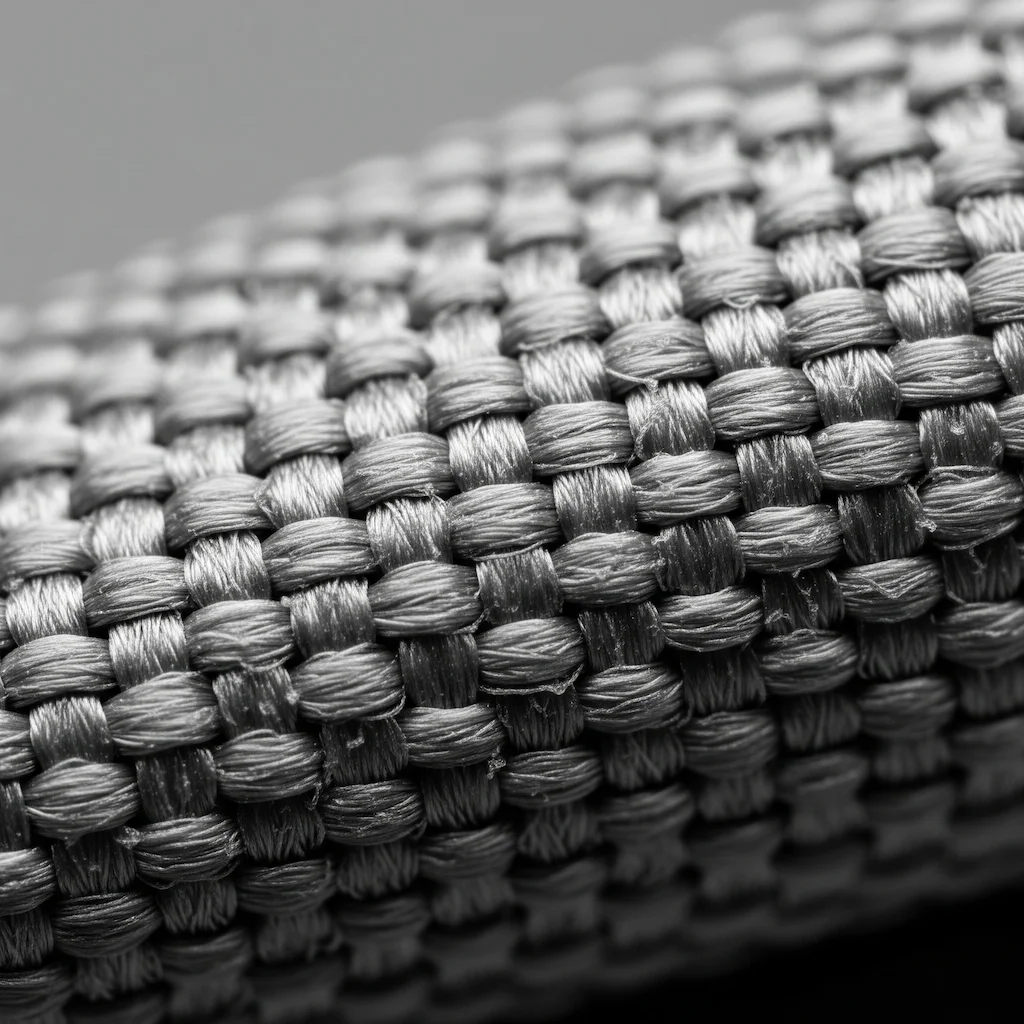

Custom Textile Development

Custom textile development for industrial lamination and thermoforming. We engineer specialized fabrics for automotive, footwear, and sports industries.Detalles.

Industrias Dreibal specializes in the engineering and manufacturing of customized textile substrates—including single jersey, woven fabrics, automotive tricot (dubetina), and non-wovens. Our materials are specifically optimized for downstream processes such as foam lamination, PSA bonding, and thermoforming.

We precision-tune parameters like grammage (GSM), knit structure, yarn count, elasticity, and finish. Furthermore, we integrate high-performance features such as antimicrobial treatments, moisture-wicking (Dry-Fit), liquid repellency, and thermal/mechanical resistance, ensuring full compatibility with PSA, Flame, or Hot-Melt lamination.

This development process is seamlessly integrated with PU, EVA, or XLPE foams to produce high-end components such as orthopedic insoles, technical linings, automotive upholstery, and impact-resistant sports gear. We deliver in master rolls, sheets, or precision-cut parts, accommodating production lines up to 2.20 m in width.

Industry data indicates that high-functionality technical textiles—driven by automotive and performance gear demands—are the fastest-growing segment due to their specialized properties. This underscores Dreibal’s commitment to providing market-leading, functional solutions.

Ficha Técnica.

Te mostramos algunos ejemplos de lo que podemos fabricar, y la ficha técnica para este tipo de solución.

Base Fabric Type

Foam Compatibility

Maximum Width

Available Finishes

Delivery Formats

Clasificaciones.

Selecciona la que desees para conocer productos relacionados y otras características.